Environmental Responsibility

Supply Chain (Environment)

Our Approach

FY2025 Highlights

-

50 biosecurity audits

in 20 farms

-

0.02% increase in biosecurity audit

average score from previous year

*Poultry farms within Sustainability Statement reporting scope.

Strengthening Environmental Accountability Across Our Supply Chain

In alignment with our Supply Chain Policy, we have reinforced our commitment to managing ESG risks throughout our supply chain by revising the Code of Business Ethics for Suppliers and Business Associates. The updated code outlines clearer expectations for environmental accountability, including pollution prevention, resource efficiency, and environmental impact mitigation. Suppliers are encouraged to identify, monitor, and minimise their environmental and carbon footprint.

To ensure the code is effectively implemented, we introduced a self-assessment form designed to evaluate suppliers’ environmental practices. This initiative was first rolled out to a group of identified high-risk suppliers, of which 80.8% met the environmental requirements outlined in the code.

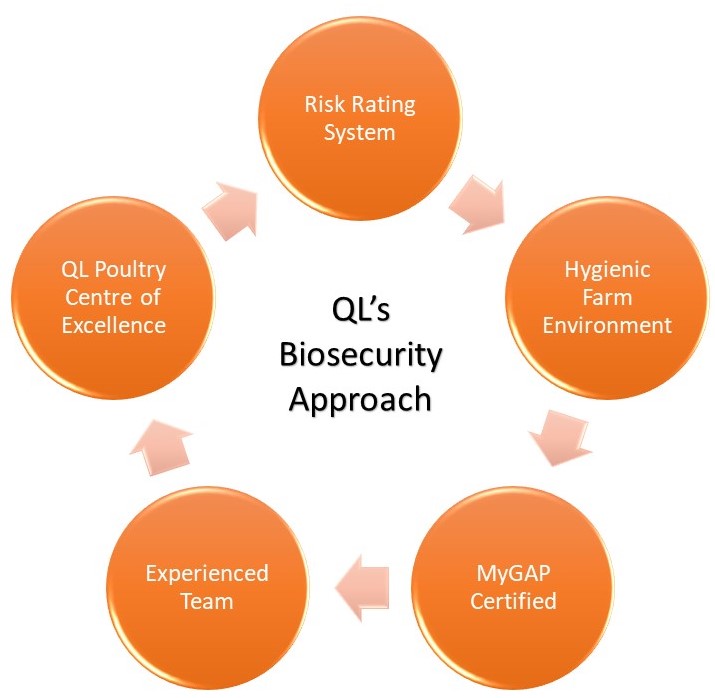

Biosecurity continues to be a cornerstone of our farm operations, ensuring the health and welfare of our poultry while minimising disease risks. Building on the progress made in previous financial year, our biosecurity initiatives in FY2025 focused on advancing infrastructure and driving innovation.

To enhance on-farm biosecurity controls, QL began preparatory work to upgrade vehicle spray and shower facilities to improve the effectiveness and efficiency of disinfection procedures for all incoming and outgoing traffic. This work is an essential measure to reduce the risk of external contamination. Additionally, we initiated planning and site preparation for a crate washing facility to support the depopulation of chickens, ensuring that transport equipment used during disease outbreaks can be thoroughly cleaned and sanitised. Furthermore, ozone disinfection trials were launched to support higher hygiene standards and enhance operational resilience.

100%

of poultry farms certified to MyGAP

100%

biosecurity assurance with internal laboratory test

TWICE A YEAR

internal audit across all poultry farms

Explore More Social Impact Stories

Rainwater Harvesting

As part of our ongoing commitment to water conservation, we continue to harvest rainwater for non-potable use, capturing runoff that

Renewable Energy

To further reduce our GHG emissions and reliance on fossil fuels, we continued to expand our renewable energy portfolio in